The Significance of a Quality Galvo Head for Specialist Laser Applications

The Significance of a Quality Galvo Head for Specialist Laser Applications

Blog Article

Comprehending Why You Required Galvo for Precision in Laser Applications

The assimilation of galvo innovation in laser applications stands for a considerable innovation in attaining accuracy and effectiveness. By using high-speed mirrors to direct the laser beam, galvo systems not just enhance operational speed however also keep the accuracy needed for complicated jobs such as inscription and cutting. This capacity is particularly vital in markets where accuracy is non-negotiable. However, comprehending the nuances of galvo systems-- including their benefits, key features, and ideal applications-- can be crucial in maximizing their possibility. Discovering these aspects may reveal vital understandings that can transform your method to laser innovation.

What Is Galvo Modern Technology?

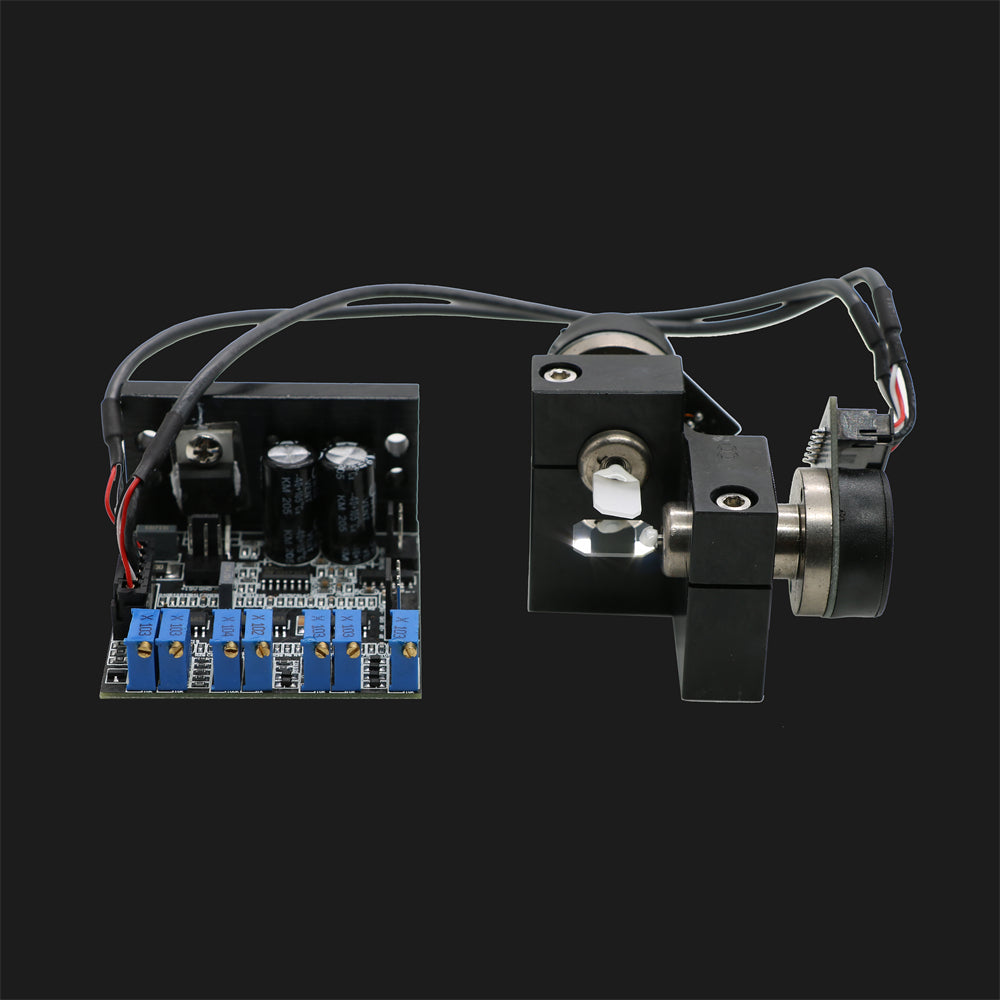

Galvo technology, short for galvanometer technology, is a precision control system that makes use of mirrors placed on galvanometer motors to direct laser beams with high accuracy. This ingenious technique allows for specific and rapid positioning of laser light, making it a crucial part in various laser applications, including engraving, cutting, and marking.

In a typical galvo system, the galvanometer motors are in charge of tilting the mirrors. The electronic control system equates the wanted laser course into electrical signals, which advise the motors to move the mirrors appropriately. This allows the laser light beam to be directed at certain angles and locations with minimal latency, boosting the performance of the laser procedure.

Galvo innovation is especially beneficial in applications that require high-speed procedure and elaborate layouts, as it decreases the mechanical movement of the laser resource. Rather, the mirrors can promptly rearrange the light beam, allowing complex patterns and layouts to be performed with accuracy. The capacity to swiftly transform the direction of the laser beam while preserving precision is what establishes galvo modern technology apart, making it a foundation of modern-day laser machinery and applications.

Benefits of Galvo Solutions

One of the essential benefits of utilizing galvo systems in laser applications hinges on their ability to boost operational speed and performance. Unlike typical laser systems that depend on relocating the entire laser head, galvo systems utilize high-speed mirrors to route the laser light beam. This significantly reduces the moment needed for positioning and permits for quick processing of facility patterns.

An additional benefit is their portable design, which helps with integration into numerous configurations without calling for substantial adjustments. This space-saving particular enables greater adaptability in laser system design, fitting varied operational atmospheres.

Additionally, galvo systems can manage a wide variety of densities and products, making them functional tools in laser handling. Generally, the benefits of galvo systems-- boosted speed, accuracy, density, and adaptability-- make them an essential choice for modern-day laser applications.

Applications in Laser Processes

Various applications in laser processes take advantage of the precision and speed given by galvo systems. These systems are indispensable to sectors such as inscription, reducing, and marking, where precision and speed directly effect productivity and item quality. In laser inscription, galvo mirrors enable fast and exact activity throughout complex surfaces, enabling elaborate layouts to be etched onto different products without jeopardizing information.

In addition, in the medical area, galvo-driven lasers are used in procedures like laser surgical procedure and cells ablation, where pinpoint precision is important for person security and efficient therapy. Galvo Scanner. On the whole, the convenience and responsiveness of galvo systems make them important in various laser applications, driving development and enhancing functional capacities across several markets

Secret Attributes of Galvo Mirrors

A critical component in laser systems, galvo mirrors are developed to supply fast and accurate light beam guiding, Continue making it possible for high-performance applications. Among the key functions of galvo mirrors is their rate; they can achieve fast angular activities, allowing for fast action times important in applications such as laser engraving, reducing, and scanning.

Another significant attribute is their high precision and accuracy. Galvo mirrors can place the laser light beam with very little discrepancy, which is crucial for jobs that need exact positioning and repeatability. This precision is assisted in by innovative control systems that can make up for any prospective mistakes in real-time.

Furthermore, the small layout of galvo mirrors permits combination into smaller systems without jeopardizing performance. Their light-weight building also adds to minimized inertia, additional enhancing their responsiveness throughout procedure.

Furthermore, the resilience and integrity of galvo mirrors make them ideal for continuous use sought after settings. This resilience makes certain constant performance gradually, minimizing downtime because of maintenance or fixings. Generally, the special attributes of galvo mirrors make them important for achieving high precision and efficiency in different laser applications.

Choosing the Right Galvo System

Selecting an ideal galvo system is essential for enhancing laser performance throughout different applications. When picking a galvo system, a number of elements must be taken into consideration to ensure compatibility with certain project demands.

An additional critical aspect is the type of laser being used. Different lasers, such as carbon dioxide or fiber lasers, have distinctive needs regarding wavelength and power, influencing the choice of galvo mirrors. Ensure that the picked system is made to deal with the certain wavelength and power of your laser for ideal performance.

Furthermore, consider the software compatibility and control options offered with the galvo system. A well-integrated software program service can improve operational performance and make it possible for precise control over scanning patterns.

Lastly, review the manufacturer's online reputation and assistance services. A reputable supplier will certainly offer not only high-grade products yet additionally ongoing technological assistance, which is vital for keeping system efficiency. By thoroughly considering these variables, you can pick a galvo system that fulfills your precise laser application requirements.

Final Thought

In recap, galvo technology plays a critical duty in improving precision and efficiency in laser applications. Picking the appropriate galvo system is crucial for maximizing efficiency in laser procedures.

The capability to quickly change the direction of the laser beam while preserving precision is what establishes galvo modern technology apart, making it a keystone of contemporary laser equipment and applications.

Unlike typical laser systems that rely on relocating the entire laser head, galvo systems my link use high-speed mirrors my latest blog post to guide the laser light beam.Many applications in laser processes profit from the accuracy and rate supplied by galvo systems (Galvo Scanner).In laser reducing applications, galvo systems improve the capability to process materials such as metal, timber, and plastics with high accuracy, ensuring clean edges and very little kerf size. Various lasers, such as CO2 or fiber lasers, have unique demands concerning wavelength and power, affecting the option of galvo mirrors

Report this page